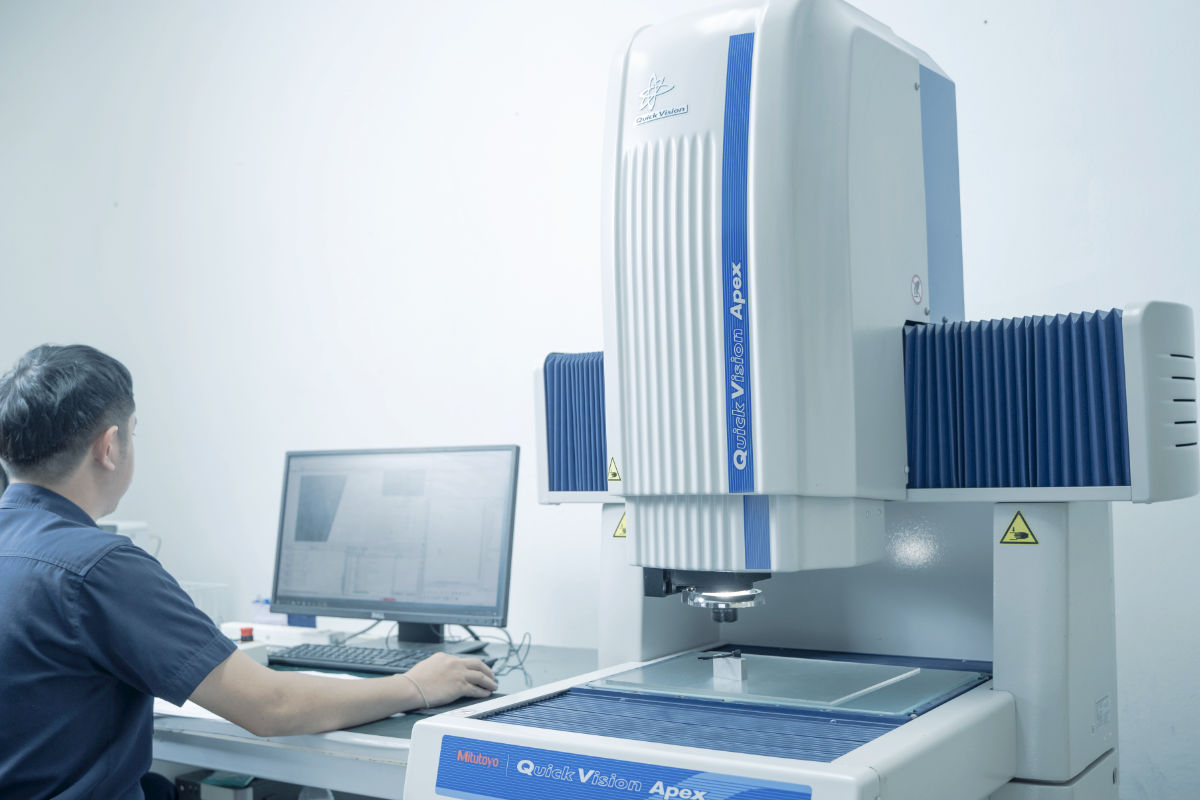

We have a strict quality inspection process

Supervised by a team of specialists who have been systematically trained in quality control. They closely monitor every step to ensure that each product meets the highest standards of accuracy, durability, and aesthetics before being delivered to customers.

At YPC, we perform strict First Piece Inspections to ensure every product starts off right, fully aligned with customer specifications and quality standards. This critical step reduces production risk, prevents costly errors, and locks in quality from the very beginning.