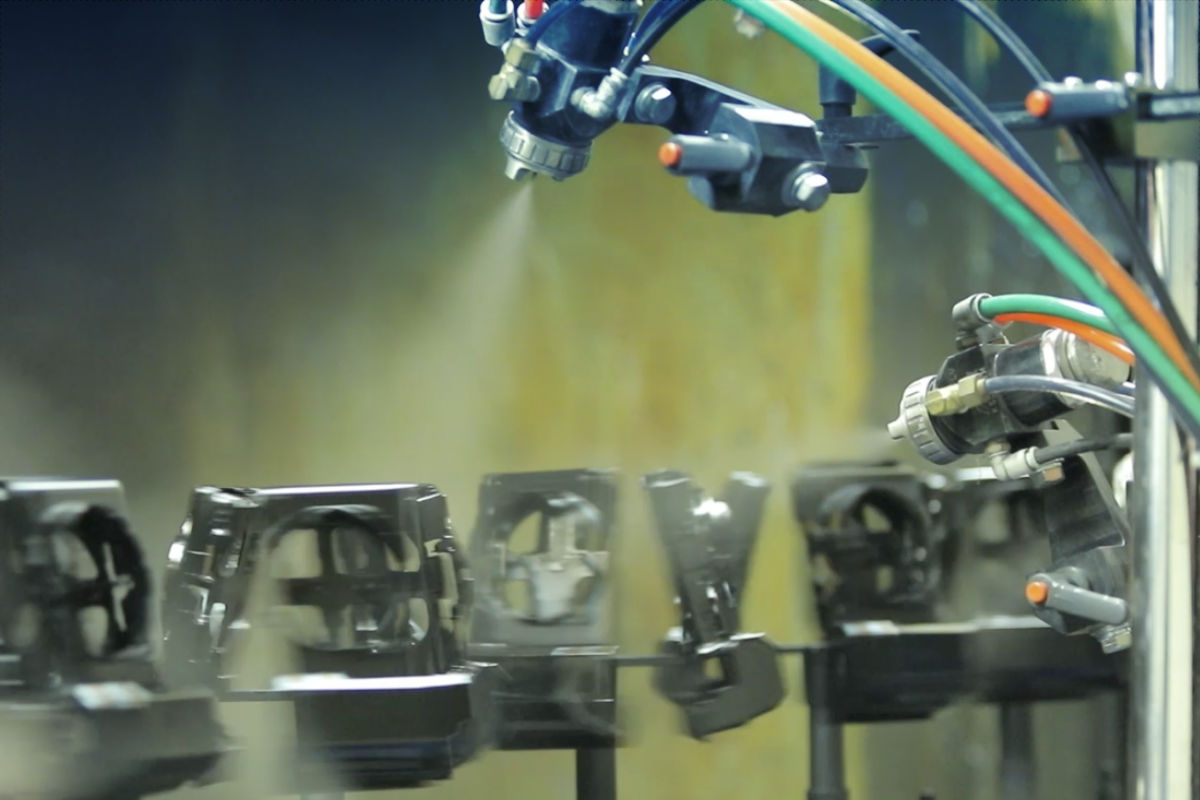

Every print we deliver is carefully controlled

For size, clarity, and consistency down to the finest detail. Our specialized printing team works hand-in-hand with high-resolution camera inspection systems to ensure accuracy and quality on every piece.

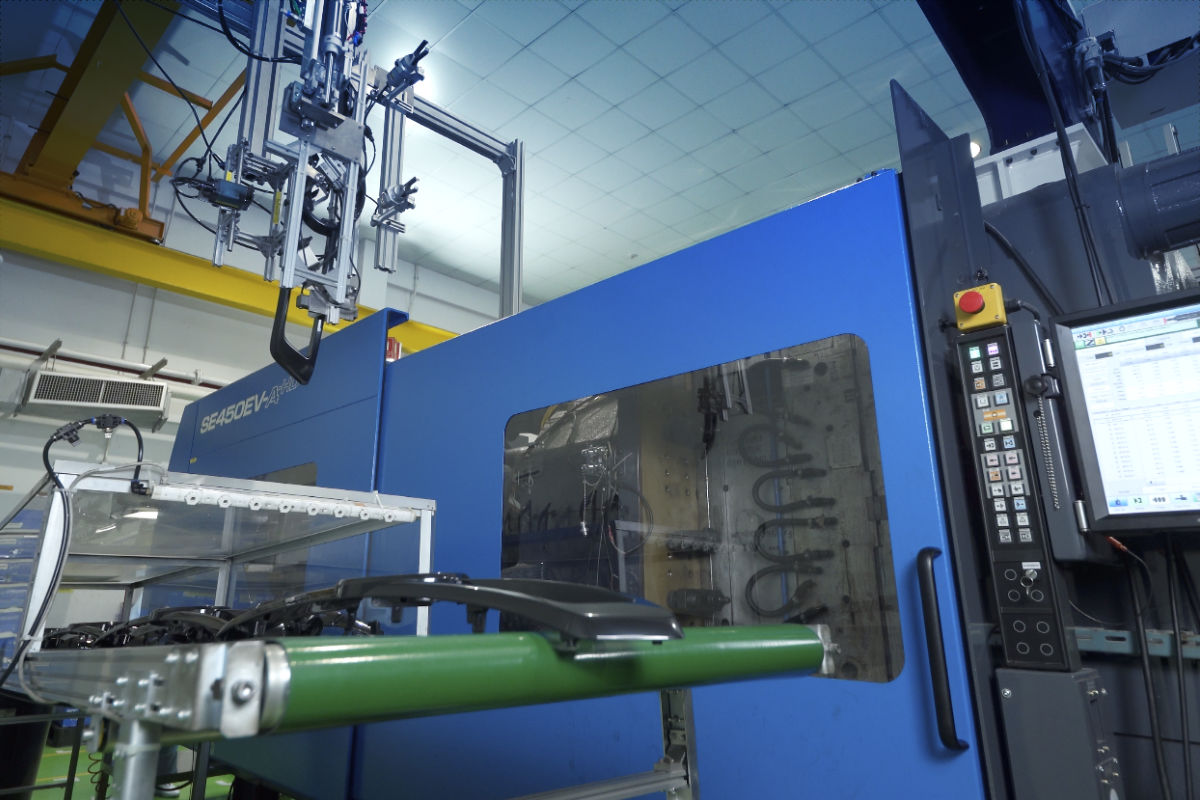

With a diverse range of printing machines, we’re equipped to handle both flat surfaces and complex geometries, allowing us to meet a wide variety of design requirements precisely, efficiently, and in full alignment with each customer’s vision.

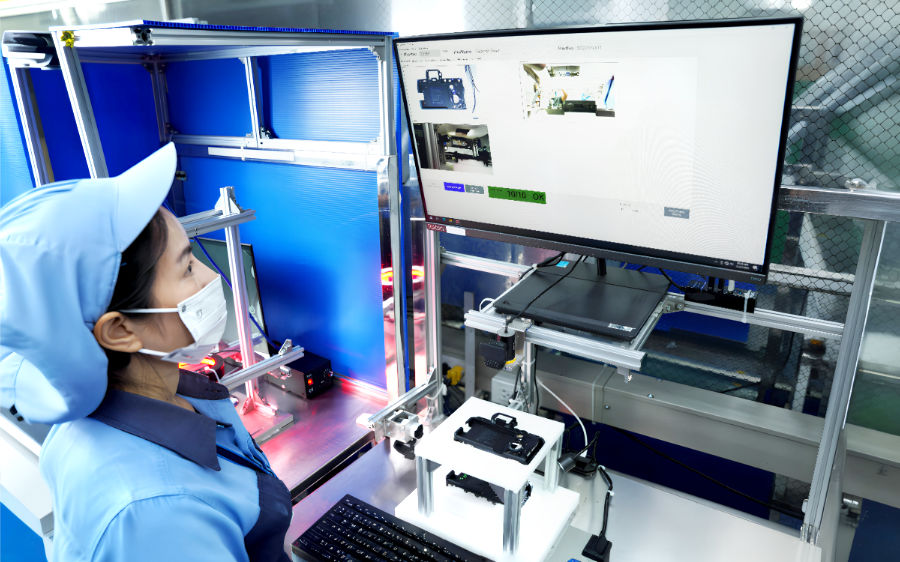

Every Part Inspected with High-Resolution Cameras

We employ advanced high-resolution camera inspection systems in our production process to capture every detail sharpness, dimensions, print accuracy, and even subtle color variations. Each part is thoroughly verified to ensure precise quality assurance, guaranteeing that our customers receive products that are flawless in every dimension.